If you customize action figures, you may have already purchased custom “3D PRINTED” parts and accessories from sellers on auction sites like eBay, Mercari, ETSY, etc. How did you like the product? Was it up to your standards? What about the price? Did you feel like you paid a fair price, or was it too expensive in your opinion? How about the turnaround shipping time? Did it arrive rather quickly or did you have to wait weeks for it to arrive in the mail? And finally, how about the overall rigidity of the item? Was it strong and sturdy that it didn’t snap in half when you were trying to fit the accessory in to your figure’s hands?

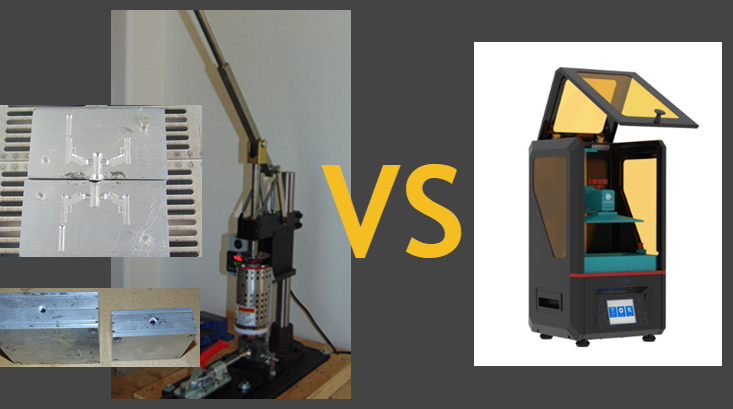

In this article, I want to go over the three advantages of Injection molded parts when compared to 3D Printed parts. Although most of the accessories we sell in our inventory are injection molded, we still 3D Print some of them. This article is NOT meant to trash talk or give sellers who 3D Print their items a bad reputation. We (M-A-D) have 3 DLP resin printers and 1 FDM printer in our shop that we use daily. And as mentioned above, we do carry accessories that are 3D Printed. So, don’t make the assumption that I am giving 3D Printed parts a bad name. I just believe that there is a place for them and it doesn’t make a whole lot of sense in some cases.

ADVANTAGES OF INJECTION MOLDED PARTS

ADVANTAGE #1 – LOW COST

One of the biggest advantages of injection molded parts for me is COST. If you’ve been shopping around eBay for accessories lately, you may have wondered how we are able to offer our accessories (miniature guns) at much lower prices compared with our competitors who 3d print their products? We’ve actually had buyers message us through eBay asking why our prices are so cheap and assumed that we are some sort of a scam! Others would ask if the shipping time really is 1 BUSINESS DAY, because they thought we were purchasing our products from China and reselling them in our store.

Well, we are NOT a scam, and we do not get any of our products pre-made from China. All of the accessories we offer for sale are 100% made in-house in our shop in California. We are able to offer at very low prices because our production cost is very low. We purchase plastic pellets in bulk that will be used for one of our injection molding machines, and that’s how we pump out miniature plastic toy guns that you all enjoy. On top of that, we also do the CNC machining in-house, when making the aluminum molds for injection molding, lowering our production costs even more. When all is said and done and you break everything down to how much each piece cost us, it is merely a fraction of what other competitors can offer.

The last time I checked, a 1 Liter bottle of 3d printer resin cost about $30. From experience, I typically get about 100 to 120 small gun pieces out of this bottle. For injection molding, I pay around $50 for 10 lbs of plastic, but I can make anywhere from 2,000 to 3,000 small gun pieces out of that 10 lb bag. So when you do the math, hands down, injection molding can save a ton of $$$ just on materials! Another reason how we get to save on production cost.

Since we get to save on production cost, we get to pass those savings on to our customers. I’m sure it is much appreciated and possibly why we get repeat customers time and time again.

ADVANTAGE #2 – VERY FAST TURN AROUND

As mentioned above, we ALWAYS offer 1 BUSINESS DAY shipping on all our products. If we receive your order before 5 PM PST, it gets packaged and labeled that same day and ships to the Post Office the VERY NEXT BUSINESS DAY!

We are able to offer this kind of service because we have thousands of pieces readily available in our inventory at any given time. With injection molding, we can make 100 pieces of one gun in about an hour. I noticed before that a lot of our competitors that 3D Print their products have a longer wait time for shipping. I realized that this is because they print and make each piece as they receive the order. There’s absolutely nothing wrong with that and I think that type of business model really works, as long as your buyers are aware and they are willing to wait.

We also offer 3D Printed accessories but we still offer 1 day shipping on them. This is because we print and post process dozens of them at a time. I didn’t think it would be fair for us to offer fast shipping services just for the guns, but not on the other accessories.

ADVANTAGE #3 – RIGID PARTS

This one is big! When I first started Mini Arms Depot (MAD), I was 3D Printing and resin casting everything! Needless to say, most of the complaints I got from my customers was that the piece snapped or it broke in half when they were trying to fit the gun into their figure’s hands. Now that our guns are injection molded, I don’t get those complaints anymore. In my opinion, 3D Printed parts are not as rigid as injection molded ones.

Now, don’t get me wrong because there are some special 3d printing resins out there that allows you to make very rigid pieces. However, these special resins usually cost a bit more than the standard ones and sometimes would require you to fine tune your printer and printer settings in order to get good results.

I’ve purchased some of these special resins in the past when I first started MAD. I even thought of using them permanently and eventually become my “go-to” resin for making accessories. I learned that although these resins worked quite well and gave me very rigid parts, they were also brittle and would sometimes shatter when I accidentally drop them.

CONCLUSION

While this article covered the PROS of injection molding when compared to 3D Printing, the next article will cover the CONS and disadvantages of injection molding. Stay tuned and until next time! Don’t forget to drop by and send us a message in the CONTACT page if you have any questions regarding any of our products.